| |

| Products : |

| |

COMPLETE RADIATOR

/ CORE ASSEMBLY |

| |

Core conventional type, having Brass Tubes, Copper Fins,

Brass Header Plates, M.S. Side Brackets, Top & Bottom

Tanks made from M.S. / Brass of required thickness,

complete in all respect. We manufacture special Radiators

(Solder Coated) suitable for Acidic , Salty & Dusty

Environment.

|

| |

| WITHNEL TUBE TYPE

RADIATOR ASSEMBLY |

| |

Core Withnel Tube type consisting of Copper Pipes, Copper

Fins ( Zig-Zag type ), Brass Header Plates, Top Tank,

Bottom Tank and Side Brackets all made from M.S.of required

thickness, complete in all respect.

|

| |

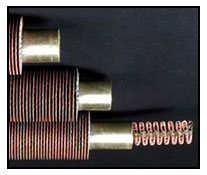

SPRING / WIRE WOUND

/ ZIG ZAG TYPE TUBES |

| |

Spring Type Finned Tubes are made from Copper / M.S.

Wire and wrapped around the outside base of the tube

with both ends brazed to the base tube. These type of

tubes are required for Oil Coolers for Drill Machines

like RECP, IDM, CPT Compressors, SBSH (Russian) Rota

Coal etc.

|

| |

SPIRAL-FINNED TUBES |

| |

These type of

fins are semi-crimped and wrapped under tension around

the outside of the base tube. Fins are either tack welded

or brazed to the base tube at each end of the tube.

Finned Tubes are the brain and backbone of the very

best Heat Exchanger unit. Finned Tube Heat Exchangers

are used in Chemical, Pharmaceutical, Textile and Food

Processing machine, Oil Refineries, Marine Industries,

Driers, Compressors, Air Heaters, etc. Finned Tubes

with better bonding of Fins gives a larger surface area

increasing the heat transfer rate and hence, as it increases

the efficiency at a reduced cost, it is more economical.

|

|

| |

| Base Tube Diameter |

: 3/8" to 4"

( 9.52mm to 114mm ) |

Fin Height |

: 1/4" to 2" |

Fin Material |

: M.S., S.Steel,

Copper, Brass,Aluminium |

Tube Material |

: M.S., S.Steel,

Copper, Brass, Aluminium |

Tube Length |

: 1ft. to 75ft. |

|

| |

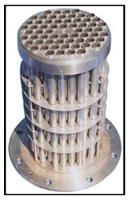

OIL COOLER ASSEMBLY |

| |

Oil Cooler Assembly made of Copper cooling tubes (with

turbulators inserted) and copper fins, M.S. fabricated

tanks and brackets in substitute of imported Aluminum

Oil Cooler. These type of Coolers are required for cooling

Hydrolic / Transmission oil in HEM / Construction Equipments.

These are high in performance and durable. We also manufacture

bigger size coolers to meet

customer requirements.

|

| |

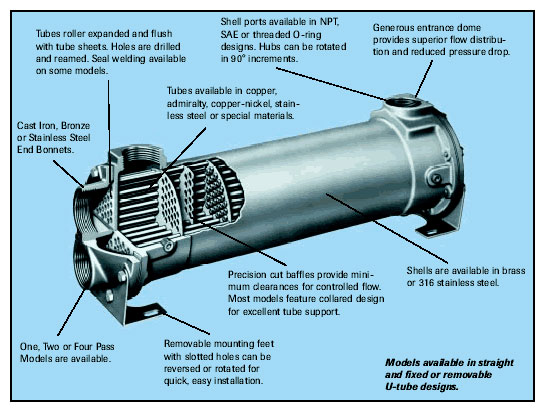

| SHELL AND TUBE TYPE HEAT EXCHANGERS

/ TRANSMISSION COOLERS |

| |

A

shell and tube heat exchanger is a device built for

efficient heat transfer from one medium to another.

It consists of a shell (a large pressure vessel) with

a bundle of tubes inside it. Two fluids of different

starting temperature flow through the heat exchanger.

One flows through the tubes (the tube side) and the

other flows outside the tubes but inside the shell (the

shell side) The fluids can be either liquids or gases

on either the shell side or the tube side. Heat is transferred

from one fluid to the other through the tube walls either

from the tube side to the shell side or vice versa.

This is an efficient way to exchange heat. A

shell and tube heat exchanger is a device built for

efficient heat transfer from one medium to another.

It consists of a shell (a large pressure vessel) with

a bundle of tubes inside it. Two fluids of different

starting temperature flow through the heat exchanger.

One flows through the tubes (the tube side) and the

other flows outside the tubes but inside the shell (the

shell side) The fluids can be either liquids or gases

on either the shell side or the tube side. Heat is transferred

from one fluid to the other through the tube walls either

from the tube side to the shell side or vice versa.

This is an efficient way to exchange heat.

These type of heat exchangers are widely used in space

heating, refrigeration, power plants, chemical plants,

petrochemical plants, petroleum refineries, cement plants,

food processing plants, etc.

Types of Heat exchangers :

- Plate type heat exchanger,

- Finned tube type heat exchanger,

- Single phase heat exchanger,

- Double phase heat exchanger,

- U - Tube heat exchanger.

|

|

| |

| |

|