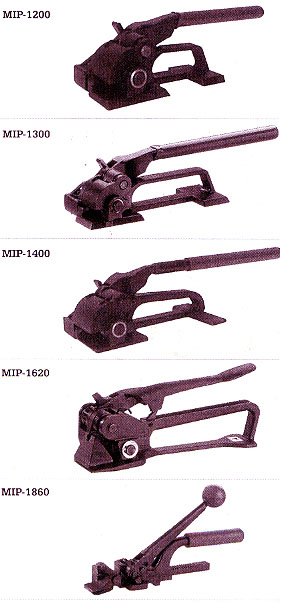

| Tensioners: |

|

|

|

|

Model

|

Type

|

Strap

Gauge

Range

(mm)

|

Strap

Width Range

(mm)

|

|

Compact Feedwheel Tensioner

Regular duty, for use with Apex steel strap

Feedwheel

Tensionei

Regular duty, for use with ApexTM steel strap

Feedwheel

Tensioner

Feedwheel Pusher Tensioner

Rack and Pinion Pusher Tensioner

|

0.38 -

0.58

0.38 -

0.63

0.63 -

0.89

0.58 -

0.89

0.58 -

0.89

|

12.70-19.05

2.70 - 19.05

19.05 - 31.75

15.87 - 31.75

15.87 - 31.75

|

| Seal-less

Combination Tool |

|

|

|

|

Seal-less

combination tool with adjustable strap guides

Regular duty for use with Apex steel strap |

Adjustable from

0.38-0.58 |

Adjustable* from 12.70-19.05

|

| Sealers |

|

|

|

|

Double

notch, down cut, front action sealer.

Regular duty, for use with ApexTM

steel strap

Single notch, up cut,front action sealer Regular duty,

for use with ApexTM steel strap

Single

notch, down

cut, side action

sealer

Double

notch, up

cut, side action

sealer

|

0.38

- 0.58

0.38 -

0.58

0.63 -

0.89

0.63 -

0.89

|

12.70

15.87

19.05

12.70

15.87

19.05

19.05

31.75

19.05

31.75

|

| Cutters |

|

|

|

|

Steel

and Polyester strap cutter

Steel strap cutter |

'0.38 - 0.89

0.63 - 1.27

|

12.7 - 31.75

19.05 - 50.8 |

|

Apex

Plus™ Steel Strapping

|

|

|

|

Product |

Size - inches |

Size - mm |

Breek Loed-Kg. |

Yield |

*

|

|

Width x thickness |

Width x thickness |

Min. |

Max. |

Mtrs./Kg |

|

Apex |

1/2 x 0.015 |

12.70 x 0.38 |

376 |

- - |

26.36 |

1 |

|

Apex |

1/2 x 0.020 |

12.70 x 0.51 |

486 |

- - |

19.64 |

2 |

|

Apex |

5/8 x 0.015 |

15.88 x 0.38 |

471 |

- - |

21.08 |

2 |

|

Apex |

5/8 x 0.018 |

15.88 x 0.46 |

555 |

- - |

17.42 |

2 |

|

Apex |

5/8 x 0.020 |

15.88 x 0.51 |

615 |

- - |

15.71 |

2 |

|

Apex |

5/8 x 0.023 |

15.88 x 0.58 |

691 |

- - |

13.81 |

2 |

|

Apex |

3/4 x 0.015 |

19.05 x 0.38 |

565 |

- - |

17.58 |

2 |

|

Apex |

3/4 x 0.020 |

19.05 x 0.51 |

728 |

- - |

13.10 |

2 |

|

Apex |

3/4 x 0.023 |

19.05 x 0.58 |

829 |

- - |

11.52 |

2 |

|

Apex |

1 1/4 x 0.031 |

31.75 x 0.79 |

1806 |

- - |

5.07 |

3 |

|

*

Application / 1-Light / 2-Medium / 3- Heavy duty

/ 4-Lashing / B-Baling

Tolerance: Width: +/ -0.13mm; Thickness: +0.05

/ -0.03 mm

Yield calculation is based on nominal width and

thickness.

Apex

Plus is a cold-rolled, medium carbon steel strapping,

engineered to yield a higher break strength

at a thinner gauge than regular-duty steel strapping.

In many light to medium-duty applications, Apex

Plus can substitute for the heavier gauge regular-duty

steel strapping to save money on material and

shipping costs.

|

|

|

Magnus®

Steel Strapping

|

|

|

|

|

Product |

Size - inches |

Size - mm |

Breek Loed-Kg. |

Yield |

* |

|

Width x thickness |

Width x thickness |

Min. |

Max. |

Mtrs./Kg |

|

Magnus |

5/8 x 0.020 |

15.88 x 0.51 |

771 |

975 |

15.71 |

2 |

|

Magnus |

5/8 x 0.023 |

15.88 x 0.58 |

884 |

1135 |

13.81 |

2 |

|

Magnus |

3/4 x 0.025 |

19.05 x 0.64 |

1134 |

1451 |

10.28 |

2 |

|

Magnus |

3/4 x 0.031 |

19.05 x 0.79 |

1383 |

1768 |

8.45 |

2 |

|

Magnus |

1 1/4 x 0.025 |

31.75 x 0.64 |

1900 |

2398 |

6.17 |

3 |

|

Magnus |

1 1/4 x 0.031 |

31.75 x 0.79 |

2313 |

2947 |

5.07 |

3 |

|

Magnus |

1 1/4 x 0.035 |

31.75 x 0.89 |

2600 |

3193 |

4.50 |

3 |

|

Magnus |

1 1/4 x 0.050 |

31.75 x 1.27 |

3673 |

4669 |

3.16 |

4 |

|

*

Application / 1-Light / 2-Medium / 3- Heavy

duty / 4-Lashing / B-Baling

Tolerance: Width: +/ -0.13mm; Thickness: +0.05

/ -0.03 mm

Yield calculation is based on nominal width

and thickness.

Magnus is a cold-rolled, heat-treated, medium

carbon steel strapping that provides high tensile

strength and excellent shock resistance for

the heaviest-duty applications.

|

|

|

|

| |

|

|

|