| |

|

| General Tip for Maintenance: General Tips For Hoses |

| |

Quick

Query: |

| » Storage: If you want your hose to last 10 years and more, here are some tips. |

- Store hose in cool, dry rooms.

- Store them away from direct sunlight and heat vents. .Keep them away from arc welders and other electrical equipment .

- Do not open hoses from original wrapping till you actually need them .

- If the hose ends are plugged when shipped, do not unplug them till ready for installation (to keep the inside of hose clean)

- Always store the hose in moderate humid atmosphere at temperature ranging from 500 to 75°

- Do not hang coiled hose on a hook.

- Hose shipped straight should be stored straight.

- Open the packing carefully when using knives or sharp tools.

|

|

|

|

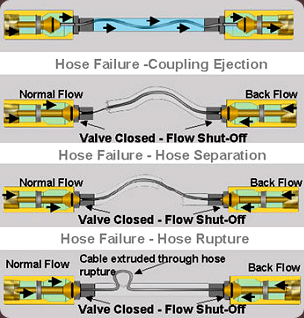

» Couplings: |

- Different types of couplings need to be used for different hoses for the sake of human safety and hose assembly life. .Use proper size couplings and install them correctly.

- Use approved couplings for steam, LP Gas, Corrosive chemicals and petroleum products.

- If the coupling comes in contact with flammable material, make sure it is made of non-sparking material such as brass or aluminium.

- Before installing couplings check them for burrs or sharp edges .

- Make sure the hose ends are cut square before installing the couplings.

- Avoid oil based and permanent lubricant when installing , couplings. Water and soap solution is a better alternative.

|

| |

» Static Electricity: |

- In some applications, it is important that the hose conducts electricity from the end of one coupling, through the hose, to the other coupling. This electrical bond, called a Static Bond, dissipates the Static Electricity that some materials generate when they pass through the hose. If this electricity is not picked up and conducted away from the material by the hose, a dangerous explosion could result .

- To discharge Static Electricity, static wires are provided in such hoses e.g. Petrol, Sandblast etc.

|

| |

» Hose Maintenance: Good maintenance results in longer life and safe working environment. Given below are few tips: |

Never exceed pressure rating of a hose. Never exceed pressure rating of a hose.

- Never allow excessive pressure spikes or surges above a hose's maximum rated working pressure.

- Never run over hose with equipment or vehicles such as forklifts.

- Do not pull a hose by its coupling, It can lead to a dangerous failure.

- Never lift a heavy, large-diameter hose by the middle with ends hanging down. This can damaged the hose's internal reinforcement .

- Support large-dia hoses, every 10 feet (approx.) with slings or rope saddles.

- Where hose is exposed to excessive wear in one spot, add an extra protective cover, such as nylon sleeve, or a pad.

- Any hose that has been mishandled, must be re-inspected and should pass a pressure test before it's re-installation.

- All hoses should be visually inspected and pressure tested regularly. This is specially important for hoses in critical applications, such as acid/chemical, steam and petroleum.

- Check for coupling seepage and coupling slippage frequently.

|