|

|

|

| |

| |

| |

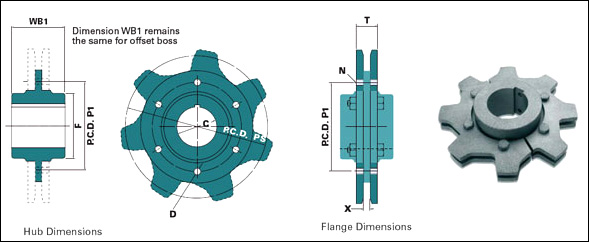

| Special Type Sprocket |

| |

|

|

| |

| |

Chain

Ref.h |

No. of

teethh |

Dia PS

mmh |

Dia P1

mmh |

Dia C mm

Maxh |

Dia D

mmh |

N No.

Holes |

T

mm |

X

mm |

WB

1 mm |

102

|

6 |

204.0 |

- |

70 |

- |

- |

29 |

9 |

83 |

7 |

235.1 |

146.1 |

70 |

12 |

6 |

29 |

9 |

83 |

8 |

266.5 |

168.3 |

85 |

12 |

6 |

29 |

9 |

83 |

9 |

298.2 |

200.0 |

105 |

12 |

6 |

29 |

9 |

83 |

10 |

330.1 |

241.3 |

105 |

12 |

8 |

39 |

9 |

83 |

142

|

6 |

284.0 |

- |

85 |

- |

- |

44 |

14 |

95 |

7 |

327.3 |

200.0 |

105 |

16 |

6 |

44 |

14 |

112 |

8 |

371.1 |

241.3 |

115 |

20 |

8 |

44 |

14 |

127 |

9 |

415.2 |

285.8 |

115 |

20 |

8 |

44 |

14 |

127 |

10 |

459.5 |

285.8 |

150 |

20 |

8 |

44 |

14 |

127 |

11 |

504.0 |

368.3 |

170 |

20 |

8 |

44 |

14 |

150 |

13 |

593.1 |

470.0 |

170 |

20 |

8 |

44 |

14 |

150 |

14 |

638.3 |

470.0 |

170 |

20 |

8 |

44 |

14 |

150 |

142H |

7 |

327.3 |

200.0 |

105 |

16 |

6 |

61 |

31 |

125 |

8 |

371.1 |

241.3 |

115 |

20 |

8 |

61 |

31 |

150 |

9 |

415.2 |

285.8 |

150 |

20 |

8 |

61 |

31 |

150 |

10 |

459.5 |

285.8 |

150 |

20 |

8 |

61 |

31 |

150 |

11 |

504.0 |

368.3 |

170 |

20 |

8 |

61 |

31 |

150 |

13 |

593.1 |

470.0 |

170 |

20 |

8 |

61 |

31 |

180 |

14 |

683.3 |

470.0 |

170 |

20 |

8 |

61 |

31 |

180 |

16 |

727.9 |

558.9 |

170 |

20 |

12 |

61 |

31 |

180 |

216 |

6 |

432.0 |

- |

140 |

- |

- |

74 |

24 |

150 |

7 |

498.0 |

311.2 |

140 |

24 |

8 |

74 |

24 |

150 |

8 |

564.1 |

381.0 |

170 |

20 |

8 |

74 |

24 |

150 |

9 |

631.5 |

430.0 |

170 |

24 |

8 |

74 |

24 |

203 |

10 |

699.0 |

490.0 |

170 |

24 |

8 |

74 |

24 |

203 |

260 |

8 |

697.4 |

451.0 |

170 |

24 |

8 |

76 |

26 |

200 |

10 |

841.4 |

625.0 |

170 |

24 |

8 |

76 |

26 |

200 |

12 |

1004.6 |

795.0 |

170 |

24 |

8 |

76 |

26 |

200 |

|

| |

| |

| |

Chain Runners Chain Runners

- Chain is normally carried on special wear resistant manganese steel runners.

- There are three typical forms of chain runners

- All three types are available in a range of sizes.

Sprockets and Trailing Wheels

- Range of quality Sprockets and Trailing Wheels to suit drop forged chain.

- Sprockets can be supplied with detachable flange segments. All wearing surfaces are hardened for improved life.

- All components are designed with full boss that includes a keyway and grub screw for secure shaft mounting.

- All components can be supplied with high strength shafts as per customers requirements.

|

| |

| |

| |

|

| |

| |

|

|

|