|

|

| |

| |

| Company's Profile : |

| |

Our comprehensive range of products with their enduring characteristics

such as durability, reliability and cost effectiveness has transformed our company

into a brand name in this segment.

With the help of our world class production facility we have leveraged our

capacity to produce products with engineered precision.

Our Level Gauges present in different categories suits all kind of industrial conditions so is the case with other product range. Our Level Gauges present in different categories suits all kind of industrial conditions so is the case with other product range.

Product Range

We cater to a diverse spectrum of industries, which adds on to our dexterity of producing quality products for all sorts of engineering needs.

Team

Our team of expert and experienced engineers, technicians, skilled and semi-skilled work force has always thrived hard to deliver better product every time. All of them have years of experience in this manufacturing segment, and it’s the continuous

and earnest efforts of all the team members that has helped in building the brand

name of the company.

Quality assurance

Our prime concern is to produce and deliver only quality products, every-time

and each time. Our manufacturing processes confirm to all the industrial

standards. To ensure the quality deliverance, we also provide our customers

with free samples of the product, so that clients can check for themselves,

if it has the desired features. |

| |

| Company Background : |

| |

In 1995, Mr. Ramesh Kumar Jaiswal formed the Ramesh Steel, a Company in

Howrah as a standard steel trader, trading steel plates, rounds and sections.

But Mr. Jaiswal is always looking

for something different than trading

business, like Machine Building, Project execution etc.

In 1997, he started machining job with materials by taking job orders

from some Engineering Industries in and around Howrah. Subsequently he

expands the business from doing small machining job work to complete

fabrication with machining job work. Then also he was not satisfied with the

job work. He wants complete machine building which may be a product of his

company.

In 2003 he formed and started Sahay Steel Industries as a manufacturing

unit of steel plant equipments and slowly he started manufacturing of CR and

HR steel coil processing equipment as a sub-vendor of Dassnagar Precision

Engineering (I) Pvt. Ltd. with the help of some Engineers.

Today Sahay Steel Industries becomes vendor of many major Steel Plant like, Bhushan Steel & Power Ltd, Essar Steel Ltd, MSPL, Arya Iron Steel Co. Pvt. Ltd., Auto Profiles Ltd, BMW Industries Ltd., Adhunik Metaliks Ltd, KIC Metaliks Ltd etc and one of the Steel Plant equipment manufacturers.

All of our products are manufactured using the high quality stainless steel, carbon steel and variations are provided on request by customers. Based on Industrial requirements we have come with different classes of valves, which suits in perfect for their specific field of applications. Proper usage of our products in its proper field of applications is the key to total customer satisfaction.

Company's Product :

Features of our products : Some of the features of our products are:

- Durable

- Reliable

- Cost effective

- Compact and sturdy

- Easy operation

- Low maintenance.

|

| |

|

| |

| Products Range : |

| |

- Roller Table.

- Pinch Rolls.

- Deflector Rolls.

- Bridle Rolls.

- Steering Rolls.

- Loop Car Rolls

- Overhung collapsible type

- Mandrels.

- Pit type Coil Car.

- Coil Transfer Car.

- Burr Mashers Rolls

- Un-coiler

- Re-coiler with pusher mechanism.

- Deflector Pinch Rolls assembly

- Hydraulic Shear

|

- Mechanical Shear

- Multi Roll Tensioners

- 5 Rolls Flatteners.

- 9 Rolls Straighteners.

- 11 Rolls Straighteners.

- 17 Rolls Levelers.

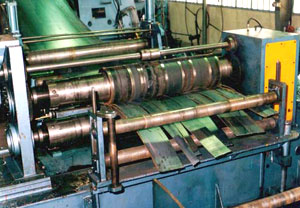

- Edge Trimmers.

- Multi cutter Strip Slitters.

- Belt Wrappers.

- Belt Conveyors.

- Hammer Head.

- Wind Box.

- Coupling.

- Guide Box-210, 155,125, 85, 60 & others.

- Pipe & Pipe Fitting's.

|

- Screw Jack

- LT & CT Wheel Assy.

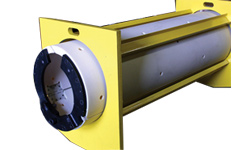

- Tail Pulley, Head Pulley, Snub Pulley.

- Breaker Roll.

- Tensioner rolls.

- Mill Coupling

- Gearbox Internals with reduce GB and drive, and any Drawing based items.

|

| |

|

|

|

|

| |

Our range of products includes:

|

|

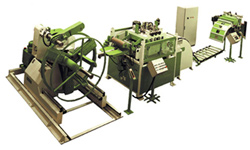

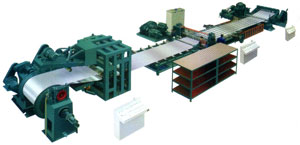

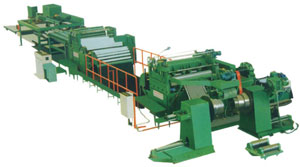

| Coil Processing Line |

Cut to Length Line |

|

|

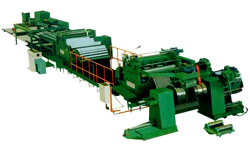

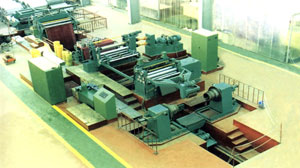

| Slitting Line |

Steel Coil |

|

|

| SMS Line Equipment |

Power Pack |

|

|

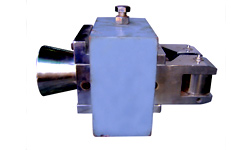

| Gear Box |

Guide and Guide Box |

|

|

| Recoiller Drum |

Hydraulics Press |

|

|

| Cylinders |

Pipe Fittings |

|

| Hot Welding Mill |

Also :

|

|

|

CR Uncoiling-slitting-recoiling line

Slitting line mainly composed of uncoiler, feeder, slitter and recoiler. Its function is to slit a wide coil to stated width strips coil along with the length direction which can be used for milling, welding pipe, cold bend forming, stamping as billet. At same time, changing different material blade can slit various metal coils.

Main technical parameter :

MODEL |

THICKNESS |

WIDTH |

COIL WEIGHT |

FINISH WIDTH |

SLITTING STRIPS |

SLITTING SPEED |

AREA NEEDED |

MAIN SHAFT DIA |

3x1600 |

0.5-3mm |

900-1 600mm |

30T |

≥40mm |

≤13 |

60m/min |

21x11 |

240 |

4x1600 |

0.5-4mm |

900-1600mm |

30T |

≥60mm |

≤13 |

50m/min |

21x11 |

260 |

6x1600 |

l-6mm |

900-1600mm |

30T |

≥60mm |

≤10 |

40m/min |

21x11 |

260 |

8x2000 |

2-8mm |

900-2000mm |

35T |

≥70mm |

≤6 |

30m/min |

30x11 |

300 |

10x2200 |

3-10nnm |

900-2200mm |

35T |

≥80mm |

≤5 |

25m/min |

35x11 |

320 |

12x2200 |

3-12mm |

900-2200mm |

35T |

≥100mm |

≤5 |

20m/min |

38x11 |

320 |

14x2200 |

3-14mm |

900-2200mm |

35T |

≥ 100mm |

≤5 |

20m/min |

38x11 |

400 |

|

|

|

High speed Uncoiling-slitting- High speed Uncoiling-slitting-

recoiling line

This line is used for coil with different specifications, through uncoiling-slitting-recoiling to needed width coil for the application of all kinds of stamping line. This line is reasonable in layout,, easy operation, high level of automation, high productivity which could processing a II kinds of CR and HR1 coil, silicon, stainless coil, colored coil, aluminum coil, galvanize coil or painted coil. This line is broadly applying in metal plate processing industry, like car, container, household, appliance, packing, construction material, etc. This line is composed of coil car, uncoiler, slitter, scrap, winder, shearer cutting coil head of tail, tension pad and recoiler, etc. as well as pendulum middle bridge, pinch device, steering device. This line is an auto coil processing equipment which integrates mechanical, electrical, hydraulic, pneumatic all together.

Main technical parameter

Model/ Name |

2 x 1300 |

2 x 1600 |

3 x 1300 |

3 x 1600 |

Coil thickness (mm) |

0.3-2 |

0.3-2 |

0.5-3 |

0.5-3 |

Coil width (mm) |

600-1300 |

600-1600 |

600-1300 |

600-1600 |

Slitting strips |

2-30 |

2-30 |

2-15 |

2-15 |

Strip width precision (mm) |

±0.1 |

±0.1 |

±0.15 |

±0.15 |

Line speed (mm) |

10-120 |

10-120 |

10-120 |

10-120 |

Coil weight(T) |

10 |

15 |

20 |

30 |

Coil I.D. (mm) |

Φ508 |

Φ 508 |

Φ 508 Φ 610 |

Φ 508 Φ 610 |

Recoiling I.D. (mm) |

Φ 508 |

Φ 508 |

Φ 508 |

Φ 610 |

Main shaft Dia. |

205 |

240 |

240 |

240 |

|

|

|

High speed Uncoiling-leveling-cut- High speed Uncoiling-leveling-cut-

to length-stacking line

This line is used for coil with different specifications, through uncoiling, leveling and cutting to length to flattened plate as needed length and width. This line is composed of coil car, double support uncoiler, pre-leveler, finish-leveler, length gauge, cut to length machine, stacker, servo driven system, etc. as well as pendulum middle bridge, pressing and guiding device and steering device.

Main technical parameter

Model/ Name |

2x1300 |

2x1600 |

3x1300 |

3x1600 |

Coil thickness (mm)'- |

0.3-2 |

0.3-2 |

0.3-3 |

0.3-3 |

Coil width (mm) |

800-1300 |

800-1600 |

800-1300 |

800-1600 |

Cutting length range (mm) |

10.0-9999 |

10.0-9999 |

10.0-9999 |

10.0-9999 |

Stacking length range (mm) |

300-4000 |

300-4000 |

300-4000 |

300-4000 |

Cutting length precision (mm) |

±0.3 |

±0.3 |

±0.5 |

±0.5 |

Leveling Precision (mm/M2) |

1-2 |

1-2 |

1-2 |

1-2 |

Leveling speed (200mm/min) |

35pcs |

35pcs |

35pcs |

3 5 pcs |

Coil weight (T) |

10 |

10 |

20 |

20 |

Roll Dia. (mm) |

85 |

90 |

90 |

100 |

|

|

|

HR coil uncoiling-leveling-cut to HR coil uncoiling-leveling-cut to

length-stacking line

This line is used for HR coil (0.5mm-25mm) with different specifications, through uncoiling-leveling-cut to length to flattened plate as needed length.

This line is composed of coil car, double support uncoiler, hydraulic pressing and guiding, shovel head, pre-leveler, finish leveler, cut to length machine, stacker, accompany electric control system, hydraulic systems, etc. as well as pendulum middle plate steering device.

Main technical parameter

| Model/ Name |

3x1600 |

6x2000 |

8x2000 |

10x2200 |

2x2200 |

16x2200 |

20x2500 |

25x2500 |

Coil thickness (mm) |

0.5-3 |

1-6 |

2-8 |

2-10 |

3-12 |

4-16 |

6-20 |

8-25 |

Coil width (mm) |

1600 |

2000 |

2000 |

2200 |

2200 |

2200 |

2500 |

2500 |

Length range (mm) |

1000-4000 |

1000-6000 |

1000-8000 |

1000-10000 |

1000-12000 |

1000-12000 |

1000-12000 |

1000-12000 |

Cutting length precision (mm) |

±0.5 |

±0.5 |

± 1 |

± 1 |

± 1 |

± 1 |

± 1 |

± 1 |

leveler roll No. |

15 |

15 |

13 |

13 |

11 |

11 |

9 |

9 |

Roller Dia |

90 |

140 |

155 |

160 |

180 |

200 |

230 |

260 |

|

|

|

Stainless steel Uncoiling Leveling, Stainless steel Uncoiling Leveling,

Cutting and Stacking Line

This line is used for stainless coil with different specifications, through uncoiling-leveling-cutting to flattened plates as needed length,

This line is composed of coil car, double head uncoiler, hydraulic pressing & guiding, shovel head, pinch device, leveler, encoder and length gauge, hydraulic pendulum shearer, feeder, pneumatic stacker, unloading car, electric system, etc. as well as rollaway nest, steering device, etc.

Main technical parameter

| Model / Name |

0.8x1000 |

0.8x1250 |

1.5x1250 |

1.5x1600 |

2x1250 |

3x1600 |

3x1600 |

3x2000 |

Coil thickness (mm) |

0.15-0.8 |

0.15-0.8 |

0.3-1.5 |

0.3-1.5 |

0.3-2 |

0.3-2 |

0.3-3 |

0.3-3 |

Coil width (mm) |

600-1000 |

600-1300 |

800-1300 |

800-1600 |

800-1600 |

800-1600 |

800-1600 |

800-2000 |

Cutting length range (mm) |

10.0-9999 |

10.0-9999 |

10.0-9999 |

10.0-9999 |

10.0-9999 |

10.0-9999 |

10.0-9999 |

10.0-9999 |

Stacking length range (mm) |

300-4000 |

300-4000 |

300-4000 |

300-4000 |

300-4000 |

300-4000 |

300-4000 |

300-4000 |

Cutting length precision (mm) |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.5 |

±0.5 |

±0.5 |

Leveling precision (mm/M2) |

1-2 |

1-2 |

1-2 |

1-2 |

1-2 |

1-2 |

1-2 |

1-2 |

Leveling speed (2000mm/min)x |

15-18 |

15-18 |

15-18 |

15-18 |

15-18 |

15-18 |

15-18 |

15-18 |

Coil weight (T) |

15 |

15 |

15 |

15 |

15 |

15 |

20 |

20 |

|

|

|

Cold Rolling Mill From HR to CR Cold Rolling Mill From HR to CR

Conversion

4 Hi or 6 Hi Single Stand Reversible Cold

Rolling Mill

Material : Hot Rolled Low Carbon Steel Strips in Coils High quality steel, Stainless Steel, Silicon Steel

Strip Width : 650/800 mm minimum, 1000/1250/1500 mm maximum

Input Strip Thickness : 1.8 mm to 4.00 mm maximum

Input Coil Diameters : Inside 508/ 610 mm for cold rolling Outside 2000 mm maximum

Coil Weight : 22 MT/30 MT maximum

Mill Speed : 200 TO 1400 MPM maximum

Output Strip Thickness : 0.12 mm to 0.30 mm

Output Coil Diameters : Inside 508 mm, Outside 2000 mm maximum

|

|

|

Pickling Line Pickling Line

Push-pull Pickling Line

Push-pull Pickling is a semi-continuous production. It is characteristic with lower consumption, easier operation and fewer accidents, moreover it can pickle many kinds of incoming material. The line can produce 100,000-600,000 tons strip annually.

Process Data

Following is the data for Push-pull Pickling hot rolled strip with the annual yield, of 400,000 tons.

Acid |

Annual Output |

Strip Thickness |

Strip Width |

Coil Weight |

Line Speed |

HCI |

400,000 t |

1.2-1.8-4.5 mm |

500-1300 mm |

Max 25 t Max |

120 m/min |

Process Flow

Pay-off Reel -»Nine-roll Leveller-»End Shear-»Riveter-»Entry Looper-»Pre-rinsing Section-»Pickling Tank -»Rinsing Tank-»Hot Air Drier-»Exit Looper-»Deflector-»Disc Shear (with scrap coiler)-»Bridle Roll -» Shear -»Oiler-»Coiler

Continuous Pickling Line

Continuous Pickling is a production line that the steel strip is pulled continuously through the acid tank and rinsing tank. The line is characteristic with high efficiency and output, and low electric consumption. The annual yield of the line is 600,000-1,000,000 tons.

Process Data

Following is the data for continuous Pickling hot rolled strip with the annual yield, of 800,000 tons.

Acid Annual Output |

Strip Thickness Strip Width |

Coil Weight Line Speed |

HCI |

800,0001 |

1.2-4.5 mm |

500-1530 mm |

Max 30 t |

Max 300 m/min |

Process Flow

Coil Prepare Station-»Coil Car-»Pay-off Reel-»Pinch Straightener-»Cutting Shear-»Welder-»l# Bridle Roll --»Entry Accumulator-»Front Tension Reel-»Descaler-»Back Tension Reel-»Picking-»Ice Water Clean-» Hot Water Clean-»Dryer-»2# Bridle Roll-»Exit Accumulator-»3# Bridle Roll-»Control Roll -»Cutting Shear -»Disc Shear-»Feeder -» 4# Bridle Roll-»Oiler-»Pinch Roll-»Tension Roll -»Unloading Car |

|

|

Degreasing & Rinsing Line Degreasing & Rinsing Line

During the galvanizing entry section or high temperature annealing, the oil or grease on the surface of the strip will affect the galvanized surface quality and conglutination of the strip. Degreasing & rinsing line is applied for removing oil, residual iron and other contamination on the strip; so as to control the value of the residual carbon and iron surface quality and cleanliness can be guaranteed, especially for the strip for automobile and household electric appliance. We can provide the following degrease line.

Electro-degreasing & Rinsing Line

When the strip runs through alkali liquid tank, and the strip is set as anode or cathode through DC with reversal polarity, then gas is created on surface of the strip, which emulsifies the oil film and separates the oil from the strip surface. It is provide by productivity practice that the processing of electrolytic degrease is better than alkali degrease in many sides, such as degreasing efficiency and quality.

Process Data

Material |

Thickness |

Width |

Coil Weight |

Oil Content |

Energy |

Plain carbon steel, low alloy steel |

0.2-2.5 mm |

300-1350 mm |

Max 25 t |

1000 mg/m2 |

Electricity, Steam |

Process Flow

Pay-off Reel-»Pinch Roll-»5-roll Straightener-»Shear-»Welder-»Pinch Roll-»Chemical Degreasing -»Electrolytic Degreasing-»Roll Scrubbing Brush-»Rinsing Roll Scrubbing Brush-»Hot Air Drier -»Shear-»Tension Reel

Chemical Degreasing & Rinsing Line

It is applied for removing animal and vegetable fat grease by saponification and removing mineral oil by emulsification. |

|

|

Hot-dip Galvanizing Line

We can provide hoi-dip galvanizing line and hot-dip galvanizing aluminium-zinc line. The galvanized strip can be applied for construction, household electric appliance, vehicle, and chemical industry etc.

Continuous Hot-dip Galvanizing Line (CGL)

We provide hot-dip continuous galvanizing line with American-Steel -Union process, which can produce galvanized sheet with normal spangles, small spangles or without spangles. The sheet is used widely for manufacture of automobile, household electric appliance, and building construction.

Process Data

Plain carbon steel, low alloy |

steel 0.18-2.0 mm |

300-1250 mm |

50-180 m/min |

80-300 g/m2 (Double) |

Electricity, Steam |

Process Flow

Pay-off Reel-»Pinch Roll I, ll-»Shear I, ll-»Welder»Entry Looper-»Degreasing & Pickling-»Annealing Fumace-»Zinc Pot-»Cooling Tower-»Water Cooling Tank-»Skin Pass-»Leveller-»Anti-fingerprint Coating & Chromate Coating-»Curing Oven-»Exit Looper-»Electrolytic Oiler-»Shear-»Tension Reel |

|

|

Electroplating Line

The production line can be designed on different technical requirements. The tin-plated strip is characteristic with precise plating weight, bright and close coating, high corrosion resistance, good welding performance, and good working qualities.

Process Data

Material : MR, D, L

Thickness : 0.18—0.55 mm

Width : 300—1250 mm

Speed : 60—300 m/min

Plating Layer : 25#~100#

Energy : Electricity, Steam

Process Flow

Pay-off Reel I, ll-» Pinch Roll I, II-»Shear I, II-»Welder-»Entry Looper-»Degreasing-»Pickling-» Electroplating Tin Hot Air Drier»Reflowing-»Water Cooling-»Chromate Coating-*Electrostatic Oiler -»Exit Looper-»Shear -»Servo Tension Reel

Electro galvanizing Line

Electroplated-zinc strip is characteristic with easy coating, good corrosion resistances, high welding performance, good working qualities. It is used widely for manufacture of automobile, household electric appliance, also for inner building material and metal furniture etc.

Process Data

Material |

Thickness |

Width |

Speed |

Weight of Plate |

Energy |

Plain carbon steel, Low alloy steel |

0.18-0.55 mm |

300-1250 mm |

60—300 m/min |

20-60 g/m2(Double) |

Electricity, Steam |

Process Flow

Pay-off Reel I, ll->Pinch Roll I, II-»Shear I, II-» Welder-»Entry Looper-»Degreasing-»Pickling -»Electroplating Zink-»Hot Air Drier-»Chromate Coating-»Electrolytic Oiler-»Exit Looper-»Shear -»Servo Tension Reel |

|

|

Color Coating Line (CCL)

Color coating is a processing of coating sheet with organic paint. The coated sheet has good characteristic such as easy printing, process ability, corrosion resistance, decoration, as well high strength and good deformability. We can provide the following lines, CCL for building, CCL for home appliance, CCL with fluorocarbon, decorative or insulation coating, Color Printing Line, as well as CCL with fingerprint resistance coating or bacteria resistance coating etc, according to your requirements.

Process Data

Raw Material : Common sheet, Galvanized

Thickness : 0.15

~ 1.5 mm

Width : 300 ~ 1550 mm

Speed : 8 ~ 15 µm

Energy : Liquefied gas, Steam and Electricity

Process Flow

Pay-off Reel I, ll-»Pinch Roll I, ll-»Head Shear-»Riveter-»Seam-pressing-»Entry Looper-»Degreasing-»Chemical Coating-»Drier-»Primer Painting Finishing Painting-»Drying Oven-»Finishing Painting-»Drying Oven Rubber Painting-»Furnace-»Hot Filming-»Cold Filming Printing-»Drying Oven-»Brighten Treatment-»Drying Oven-»Exit Looper-»Shear-»Servo Tension Reel |

|

|

Straightening and leveler machine

Type |

Max T |

Width |

Roller |

Diameter |

Center distance |

. Speed |

tolerance |

Power |

JPG(0.5 ~ 3) x 1600 |

3 |

1600 |

15 |

Φ 90 |

95 |

I 30 |

2mm/m2 |

30 |

JPG(1~ 6) x 2000 |

6 |

1250 |

15 |

Φ 140 |

162 |

30 |

2mm/m2 |

55 |

JPG(2 ~ 8) x 2000 |

8 |

1600 |

13 |

Φ 155 |

170 |

25 |

2mm/m2 |

75 |

JPG(2 ~ 10) x 2200 |

10 |

600 |

13 |

Φ 160 |

180 |

25 |

2mm/m2 |

99 |

JPG(3 ~12) x 2500 |

12 |

1600 |

11 |

Φ 180 |

200 |

24 |

2mm/m2 |

110 |

JPG(4 ~ 16) x 2500 |

16 |

1600 |

11 |

Φ 200 |

230 |

23 |

2mm/m2 |

132 |

JPG(6 ~ 20) x 2500 |

20 |

2000 |

9 |

Φ 230 |

300 |

18 |

2mm/m2 |

145 |

JPG(8 ~ 25) x 2500 |

25 |

1600 |

9 |

Φ 260 |

350 |

18 |

2mm/m2 |

160 |

JPG(9 ~ 32) x 2500 |

32 |

2000 |

9 |

Φ300 |

380 |

16 |

2mm/m2 |

200 |

Slitter

Simple slitting and cut to length machine

|

|

|

Corrugated roil forming machine

Corrugated sheets are favored widely by beautiful appearance, firm and light structure and economical cost, they have occupied important position in the building field. Each region and each nation has own special styles and habit, we can design different shapes to satisfy different requirement.

Type |

Thickness |

Width |

YX40-205-1025 |

0.4-0.6mm |

1250mm |

YX28-207-828 |

0.4-0.6mm |

1000mm |

YX51-226-678 |

0.8-1.5mm |

1000mm |

YX75-200-600 |

0.8-1.5mm |

1000mm |

Type |

Thickness |

Width |

YXl8-76-760 |

0.3-0.8mm |

1000mm |

YX28-205-820 |

0.3-0.8mm |

1000mm |

YX25-210-840/15-225-900 |

0.3-0.8mm |

1000mm |

YX45-200-1000 |

0.3-0.8mm |

1250mm |

We can design the machines as per different profiles. |

|

|

Cold forming machine

C and Z purlin machine. One machine can produce different sizes by adjusting the positions rollers, do not need change roller mould. It is very simple and convenient and satisfies different requirements.

|

|

|

Roll Forming Machine :

YX206 - 610

No-girder and columniation roll forming machine

Express Guarding forming machine |

|

|

Embossing machine

Decoiler/Embosser/Cutter or Recoiler

Embossing material: stainless steel, carbon steel, aluminum, copper plate or coil.

Thickness: 0.2 to 2.0mm Various pattern |

|

| |

|

|

| |

| |

| Company's Clientele : |

| |

With our years of experience spanning more than two decades, we have earned ourselves the faith & trust of a long list of reputed clients. We have always ensured that, only the products that have undergone all sorts of checks and tests are delivered to our customers, for all these years. |

| |

| Some of our reputed clients are : |

| |

Adhunik Metaliks Limited. Adhunik Metaliks Limited.- Arya Iron & Steel Company (P) Ltd.

- Auto Profiles Limited.

- Bhusan Steel Limited.

- Bhusan Power Limited.

- BMW Limited.

- BRG Group.

- Dasnagar Precession Engineering (I) Pvt. Ltd.

- Electro Steel Limited.

- Essar Steel Limited.

- KIC Metaliks Limited.

- Leak Proof Engineering (I) Pvt. Ltd.

- MID India.

- MSPL.

- Premier Supplies & Services Pvt. Ltd.

- Super Smelters Limited.

- VSM Ispat Limited and Others.

|

| |

|

| |

|

|

|

|

|

|