|

|

|

|

|

Paper Covering Machine ...

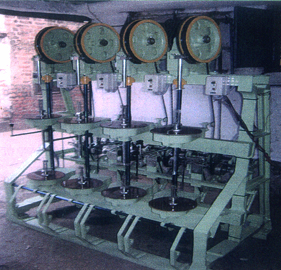

FOUR HEAD HIGH SPEED INDIVIDUAL DRIVEN DOUBLE PAPER COVERING VERTICAL MACHINE FOR WIRE:

VERTICAL TYPE DPC FOUR HEAD WIRE COVERING MACHINE.THIS MACHINE IS DESIGNED TO MEET THE CHALLENGE OF TODAYS 21st CENTURY. IT IS AN HIGH SPEED MACHINE WITH NOT HAVING LEATHER CONE FRICTION DRIVE, IT OPERATES WITH FRICTION CLUTCH WITH 1/2 HP MOTOR FITTED TO EACH HEAD, AS LEATHER CONE DRIVE MACHINE DO NOT PORVIDE PROPER RPM TO THE SPINNER WHEN THE DIAMETER OF THE LEATHER REDUCES IN RESULT WE GET LESS PRODUCTION, BUT WITH INDIVIDUAL DRIVE WE ALWAYS GET ACCURATE RPM WHICH INCREASES THE PRODUCTION CAPACTY FOR MORE THAN 30% THAN THE LEATHER CONE DRIVEN MACHINE, AND ALSO SAVES THE COST OF ELECTRICITY BY SWITCHING OFF THE HEAD/MOTOR WHICH IS NOT IN USE. CAPACITY 25 SWG TO 14 SWG FOR COPPER WIRE & 21 SWG TO 10 SWG FOR ALUMINIUM WIRE. MACHINE MANUFACTURED FROM DOUBLE HEAD TO SIX HEAD PAPER PAD 8" DIA X 2" BOREFEED DRUM 12" DIA X 8" WTDE. RECEPTION DRUM 14" DIA X 7" WIDE. HEAD FITTED WITH WIRE TENSION COMPENSATING DEVICE, HAVING CHANGE GEAR SYSTEM FOR PERCENTAGE OF LAPPING TO WIRE. HAVING AUTOMATIC LAPPING AND LAYERING SYTEM, EACH HEAD OPERATES INDEPENDENTLY AND ARE ENGAGED BY AN HAND LEVER.

VERTICAL TYPE DPC FOUR HEAD WIRE COVERING MACHINE.THIS MACHINE IS DESIGNED TO MEET THE CHALLENGE OF TODAYS 21st CENTURY. IT IS AN HIGH SPEED MACHINE WITH NOT HAVING LEATHER CONE FRICTION DRIVE, IT OPERATES WITH FRICTION CLUTCH WITH 1/2 HP MOTOR FITTED TO EACH HEAD, AS LEATHER CONE DRIVE MACHINE DO NOT PORVIDE PROPER RPM TO THE SPINNER WHEN THE DIAMETER OF THE LEATHER REDUCES IN RESULT WE GET LESS PRODUCTION, BUT WITH INDIVIDUAL DRIVE WE ALWAYS GET ACCURATE RPM WHICH INCREASES THE PRODUCTION CAPACTY FOR MORE THAN 30% THAN THE LEATHER CONE DRIVEN MACHINE, AND ALSO SAVES THE COST OF ELECTRICITY BY SWITCHING OFF THE HEAD/MOTOR WHICH IS NOT IN USE. CAPACITY 25 SWG TO 14 SWG FOR COPPER WIRE & 21 SWG TO 10 SWG FOR ALUMINIUM WIRE. MACHINE MANUFACTURED FROM DOUBLE HEAD TO SIX HEAD PAPER PAD 8" DIA X 2" BOREFEED DRUM 12" DIA X 8" WTDE. RECEPTION DRUM 14" DIA X 7" WIDE. HEAD FITTED WITH WIRE TENSION COMPENSATING DEVICE, HAVING CHANGE GEAR SYSTEM FOR PERCENTAGE OF LAPPING TO WIRE. HAVING AUTOMATIC LAPPING AND LAYERING SYTEM, EACH HEAD OPERATES INDEPENDENTLY AND ARE ENGAGED BY AN HAND LEVER.

|

Top...

|

DOUBLE PAPER COVERING VERTICAL MACHINE FOR WIRE FOUR HEAD:

VERTICAL TYPE DPC FOUR HEAD WIRE COVERING MACHINE.

CAPACITY 25 SWG TO 14 SWG FOR COPER WIRE & 21 SWG TO 10 SWG

FOR ALUMINIUM WIRE.

MACHINE MANUFACTURED FROM DOUBLE HEAD TO SIX HEAD.

PAPER PAD 8" DIA X 2" BORE IS REQUIRED.

FEED DRUM 12" DIA X 8' WIDE.

RECEPTION DRUM 14" DIA X 7" WIDE.

PRODUCTION CAPACITY- 16 SWG ALUMINIUM WIRE APPROX 80Kg IN

FOUR HEADS/8HRS OPERATION. COPPER WIRE 240Kg/8Hrs Operation.

BUT THE PRODUCTION DEPENDS UPON THE THICKNESS OF WIRE.

HEADS FITTED WITH WIRE TENSION COMPENSATING DEVICE,HAVING

CHANGE GEAR SYSTEM FOR PERCENTAGE OF LAPPING TO WIRE.

HAVING AUTOMATIC LAPPING AND LAYERING SYTEM, EACH HEAD

OPERATES INDEPENDENTLY AND ARE ENGAGED BY AN HAND

LEVER. |

Top...

|

DOUBLE PAPER COVERING VERTICAL MACHINE FOR WIRE DOUBLE HEAD : DESCRIPTION OF MACHINE.

VERTICAL TYPE DPC DOUBLE HEAD WIRE COVERING MACHINE. CAPACITY 25 SWG TO 14 SWG FOR COPER WIRE & 21 SWG TO 10 SWG FOR ALUMINIUM WIRE.

DESCRIPTION OF MACHINE.

VERTICAL TYPE DPC DOUBLE HEAD WIRE COVERING MACHINE. CAPACITY 25 SWG TO 14 SWG FOR COPER WIRE & 21 SWG TO 10 SWG FOR ALUMINIUM WIRE.

MACHINE MANUFACTURED FROM DOUBLE HEAD TO SIX HEAD.

PAPER PAD 8" DIA X 2" BORE IS REQUIRED.

FEED DRUM 12" DIA X 8' WIDE.

RECEPTION DRUM 14" DIA X 7" WIDE.

PRODUCTION CAPACITY- 16 SWG ALUMINIUM WIRE APPROX 40Kg IN DOUBLE HEADS/8HRS OPERATION. COPPER WIRE 120Kg/8Hrs Oper. BUT THE PRODUCTION DEPENDS UPON THE THICKNESS OF WIRE. HEADS FITTED WITH WIRE TENSION COMPENSATING DEVICE, HAVING CHANGE GEAR SYSTEM FOR PERCENTAGE OF LAPPING TO WIRE. HAVING AUTOMATIC LAPPING AND LAYERING SYSTEM, EACH HEAD OPERATES INDEPENDENTLY AND ARE ENGAGED BY AN HAND LEVER. |

Top...

|

SIX HEAD HIGH SPEED INDIVIDUAL DRIVEN DOUBLE PAPER COVERING VERTICAL MACHINE FOR WIRE:

VERTICAL TYPE DPC SIX HEAD WIRE COVERING MACHINE. THIS MACHINE IS DESIGNED TO MEET THE CHALLENGE OF TODAYS 21st CENTURY. IT IS AN HIGH SPEED MACHINE WITH NOT HAVING LEATHER CONE FRICTION DRIVE, IT OPERATES WITH FRICTION CLUTCH WITH 1/2 HP MOTOR FITTED TO EACH HEAD, AS LEATHER CONE DRIVE MACHINE DO NOT PORVIDE PROPER RPM TO THE SPINNER WHEN THE D1AMETER OF THE LEATHER REDUCES IN RESULT WE GET LESS PRODUCTION, BUT WITH INDIVIDUAL DRIVE WE ALWAYS GET ACCURATE RPM WHICH INCREASES THE PRODUCTION CAPACTY FOR MORE THAN 30% THAN THE LEATHER CONE DRIVEN MACHINE, AND ALSO SAVES THE COST OF ELECTRICITY BY SWITCHING OFF THE HEAD/MOTOR WHICH IS NOT IN USE. CAPACITY 25 SWG TO 14 SWG FOR COPER WIRE & 21 SWG TO 10 SWG FOR ALUMINRJM WIRE. MACHINE MANUFACTURED FROM DOUBLE HEAD TO SIX HEAD, PAPER 2" BORE, FEEDDRUM, 12" DIA X 6" WIDE. RECEPTION DRUM 14" DIA X7" WIDE. HEAD FITTED WITH WIRE TENSION COMPENSATING DEVICE, HAVING CHANGE GEAR SYSTEM FOR PERCENTAGE OF LAPPING TO WIRE. HAVING AUTOMATIC LAPPING AND LAYERING SYTEM, EACH HEAD OPERATES INDEPENDENTLY AND ARE ENGAGED BY AN HAND LEVER. |

Top...

|

DOUBLE PAPER COVERING VERTICAL MACHINE FOR STRIP:

VERTICAL TYPE DPC STRIP COVERING MACHINE (SINGLE HEAD) CAPACITY 4 MM TO 14 MM WIDE STRIP, 1.5 TO 5 MM THICK STRIP OF ALUMINIUM AS WELL AS COPPER. FITTED WITH REDUCTION GEAR BOX AND FRICTION CLUTCH TO DRIVE AND RUN THE MACHINE WITH A COIL STAND AND A STRIP STARTENER. PAPER PAD 8" DIA X 2" BORE AND WIDTH UPTO 20 MM. 2HP/1440 RPM/440V MOTOR IS NEEDED TO RUN THE MACHINE. THE SAME MACHINE CAN BE USED FOR T.P.C AS WELL AS Q.P.C BY JUST USING A SIMPLE ATTACHEMENT.

VERTICAL TYPE DPC STRIP COVERING MACHINE (SINGLE HEAD) CAPACITY 4 MM TO 14 MM WIDE STRIP, 1.5 TO 5 MM THICK STRIP OF ALUMINIUM AS WELL AS COPPER. FITTED WITH REDUCTION GEAR BOX AND FRICTION CLUTCH TO DRIVE AND RUN THE MACHINE WITH A COIL STAND AND A STRIP STARTENER. PAPER PAD 8" DIA X 2" BORE AND WIDTH UPTO 20 MM. 2HP/1440 RPM/440V MOTOR IS NEEDED TO RUN THE MACHINE. THE SAME MACHINE CAN BE USED FOR T.P.C AS WELL AS Q.P.C BY JUST USING A SIMPLE ATTACHEMENT.

Top... |

|

|

|

|

|

|

GENERAL DISCRIBTION OF DOUBLE PAPER COVERING HORIZONTAL MACHINE FOR STRIP :

1. Capacity : Strip of 4mm to 20mm wide, 1.5 to 5mm thick, Strip of aluminium as well copper. 1. Capacity : Strip of 4mm to 20mm wide, 1.5 to 5mm thick, Strip of aluminium as well copper.

2. Paper and dimension : 9" to 10" Dia, Bore 50mm, Width 8to 20mm.

3. Covering Spinner : 2Nos having Two papers moving clock wise and the last one moves anticlockwise.

4. Pay-Off : Roll in type with brake arrangement.

5.Take-Up : Suitable for spool having flange dia 750mm,bore 40mm, width 240mm.

6. Automatic Traverse : By Cross threading traverse.

Horizontal Double Paper Covering Machine Consists of the following Sub Assemblies.

- Pay-Off Supply stand roll in type with brake arrangement. INo.

- Straighter Assembly. INo.

- Multi Lapping head with 2paper pad. 2Nos.

Main machine consists of the following: -

- Multi covering spinner Gear Box 2Nos.

- D.C Motor- l Hp INo.

- Controller Panel for 1 HP DC motor INo.

- Capstan Unit with gear box: INo.

- Take up unit driven by chain sprocket INo.

General Description.

Pay-off:- The system consists of roll in type and brake arrangement. It will help for quick loading/unloading

of reel/bobbin with the manual support. It can be loaded easily by one worker. The reel/bobbin can be

inserted on the axle and removed directly from the floor. The stand is suitable upto 30" Flange

Straightening Roll.:- The straightening roll serves to feed the wire/Strip to the spinner at perfect angle. Straightening device of roll 5Nos mounted in horizontal position and 7 nos mounted in vertical position.

Capstan Unit. :- The unit drives with 740mm dia capstan wheel fitted with our standard reduction gear box with change gears

Take-Up : - The take up unit consists the following items :-

1. Main drive to take up init is given by chain drive from the capstan gearbox through main clutch.

2. Automatic traverse with cross threading arrangement. To accommodate 700mm wooden bobbin. |

|

|

| We also manufacture multilayer strip covering machine (for 12 layers / 16 layers / 18 layers & 24 layers ) and as per your requirement. |

|

|

|

| Top... |

|

|

|

|

Powered by: |

|

|