| |

|

Services |

| |

-

|

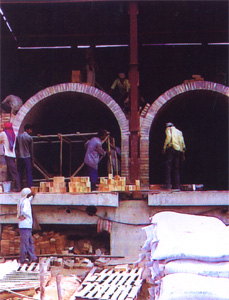

Bengal Energy Ltd’s Non-recovery

Coke Oven – a Rs 900 crore project

under construction, where Mr S. N.

Laha was Consultant (Refractor |

REFRACTORIES

- Design, Selection, Inspection & Testing,

R&D / Formulation of Products Sourcing, Application

Engineering, Installation of Products: Bricks/ Monolithics,

Precast Shapes, Steel Fiber Reinforced Refractories,

Raw Material Sourcing & its Evaluation, Marketing

etc.

- ENERGY SAVINGS -

All types of Kilns, Ovens, Furnaces, Kiln Furniture

& Low Thermal Mass Car for Tunnel & Shuttle

Kilns

- TRAINING & PROCESS

CONTROL -

- Ceramic Tiles

- Sanitary wares

- Stoneware Pipes

- Crockeries

- Refractories

- Fly-Ash based Products.

- NON-RECOVERY COKE

OVEN - Total Refractory Management.

Composite Coke Oven Door (Leak Proof, low

Heat Loss & Long Life) - Patent Application :

711/KOL/2005, Dated 08.08.2005

- Ceramic Fiber Hot Face Working

Lining for N/R &

H/R Coke Oven Roof -

Patent Application : 827/KOL/2005, Dated

09.09.2005

- FLY ASH BASED PRODUCTS

– Medium to Small Scale Projects &

High Value Items

|

| |

|

Composite door (front view) developed by

NCCS

for

Nonrecovery

Coke Oven.

Mr S. N.

Laha is

seen to

inspect the

installation work |

TECHNOLOGIES

FOR TRANSFER

- Cordierite- Mullite Kiln

Furniture : Sanitarywares / Tiles /

Crockeries

- Mullite Kiln Furniture

/ Burner Block ( Super High Thermal

Shock Resistance) : Ceramic.& Glass Industry.

- Super Duty

Silica Brick : Crown of Glass Tank

Furnace

- Refractory Castable with

Controlled +Ve Expansion for High Alumina

Roof Repairing of Tunnel and Shuttle Kilns

- High Temp. Coating for Cer Rollers, Ceramic Tiles

- Composite Coke Oven Door (Leak proof low Heat Loss & Long Life):

Patent Application No. 711/KOL/2005

- Ceramic Fiber. Hot Face Lining For NR / HR

Coke Oven Roof : Patent Application

No. 827/KOL/2005, Dated 09.09.2005

|

| |

Consultancy and

Services Include

- Consultancy

and technical solutions related to refractories,

inspection and testing, and project (concept

to commissioning) related to refractories

and ceramics.

-

R&D,

product development, innovative design development

and engineering for refractory lining,

specification and selection of refractory,

installation, maintenance technique, heat

transfer calculation of monolithic and bricks

through software application engineering,

failure analysis and repair.

-

|

Event Management :

Exhibition of Refractory Products |

Market

survey and preparation of techno-economic

feasibility study report.

- Preparation of detailed

project report (DPR); project jobs from concept

to commercialization (small to medium size)

:

- (a) Refractories (conventional

& high-tech)

- (b) Fly ash based products

- (c) Ceramic tiles (wall

and floor)

- (d) Sanitarywares

- (e) Stoneware pipes

- (f) Metal-ceramic composites

& Precast shapes

- Guidance

on formulation of products (bricks and monolithic)

and process control in manufacturing

of ceramics, refractories (bricks and monolithic)

and allied products.

- Inspection and testing of

refractories.

- Energy saving for kilns,

furnaces and ovens.

- Materials engineering and

appropriate selection of materials for different

service conditions.

- Newer

products, viz. Composites (metal-ceramic,

carbon-polymer-ceramic, etc) development and

production for effective end use.

|

| |

Refractory and Ceramic

Products from NCCS

-

85% alumina refractory plastic,

an import substitution for application in Induction

furnace, Spout / Laddle melting Co-Cr-W-C and

Ni-Cr-Fe-Si hard facing alloys.

-

|

S.N.Laha, Consultant,

Ceramic Tile Project,

KSGL, Baruipur with Mr.

Buddhadev Bhattacharjee, Hon'ble Chief Minister

of W.B. |

Mullite brick with super high

thermal shock resistance as kiln furniture /

glass industry application.

- Cordeirite-mullite kiln furniture

for sanitaryware / tile industry.

- Super duty silica brick for crown

of glass tank furnace.

- Composite (metal-ceramic, carbon-polymer)

door for coke oven – patent pending (2005).

- Ceramic fiber hot face working

lining for coke oven – patent pending

(2005).

- Steel fiber reinforced castable

(SFRC), a metal ceramic composite.

- Monolithic refractory lance for

steel industry.

- 95% zirconia nozzle for continuous

casting of steel.

- Zirconia-alumina-carbon and alumina-carbon

slide gate refractories.

- Alimina chrome brick for steel

ladle.

- Refractory castable with controlled

positive expansion.

- Low cement castable, 75-80% Al2O3

PCPF : steel reheat furnace hearth.

- High temperature coating for ceramic

rollers : tile industry.

- Iron oxide doped high cond. silica

checker bricks.

|

|

|

S.N.Laha (right

middle) with J.R.D. Tata, Chairman, Tata Group

of Industries

at IITF, New Delhi |

The company served many organizations

as consultant (refractories) to provide technical

solutions for various refractories and process

problems. The company is responsible for manpower

(foreign) selection, sourcing and standardization

of raw materials, commissioning and production

to achieve 100% capacity utilization for new project.

Also the company helps for implementation of project

including sourcing of raw materials for body and

glazes, laboratory set-up and commissioning, etc.

Natasha Ceramics

and Consultancy Services provides techno-economics’

feasibility report including market survey for

multinational and other various companies in India

and abroad. The company is also committed to provide

environmental friendly innovative technology,

products and processes to industries globally,

which critically improve efficiency and reduce

cost. In the new horizon of industrial development

in the country, ceramic industries are getting

more importance, where the company can provide

intensive knowledge input towards the growth. |

|