|

|

|

|

| |

| Tubular Heating Elements... |

|

| |

|

The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually any configuration. The basic design consists of a helical coil of nickel-chromium resistance wire embedded in a magnesium oxide insulating material. The cross section design of the metal sheath assures maximum strength and rigidity. The tubular design also permits ready bending and forming to fit a wide range of applications, without damage to the heating coil or insulation material. The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually any configuration. The basic design consists of a helical coil of nickel-chromium resistance wire embedded in a magnesium oxide insulating material. The cross section design of the metal sheath assures maximum strength and rigidity. The tubular design also permits ready bending and forming to fit a wide range of applications, without damage to the heating coil or insulation material.

Copper Sheath: For water heating & for heating water solutions which are non-corrosive to copper.

Steel Sheath: Immersion in oils, molten salt baths, alkaline cleaning solutions, tars and asphalt. Suitable for casting into aluminum.

Stainless Steel Sheath: Corrosive liquids, food processing equipment.

Incoloy Sheath: Air heating, radiant heating, cleaning and degreasing solutions, plating and pickling solutions, corrosive liquids.

Other sheath materials are also available for application considerations. Commonly specified are SS 304, SS 316, SS 321 & Incoloy tubes along with titanium for severely corrosive solution heating. |

| |

| |

| Global Heating Specialist |

|  In any Thermal Power Plant Electrostatic Precipitation (ESP) forms an integral part of Fly Ash Collecting System which plays vital role in the control of TPM present in the flue gases. For the smo In any Thermal Power Plant Electrostatic Precipitation (ESP) forms an integral part of Fly Ash Collecting System which plays vital role in the control of TPM present in the flue gases. For the smo oth functioning of ESP, the heating elements provided at hopper and support and shaft insulator play an important role. The heater in ESP hopper are provided to avoid clinker formation of the ash being collected at the bottom of ESP. Whereas the heaters provided at the shaft and support insulators are required to maintain thetemperature above dew point which lies between 80-115 deg C. If temperature falls below the range as mentioned there will be a continuous tracking of electrical field over the surface of insulator which will result into damage of insulator and non a oth functioning of ESP, the heating elements provided at hopper and support and shaft insulator play an important role. The heater in ESP hopper are provided to avoid clinker formation of the ash being collected at the bottom of ESP. Whereas the heaters provided at the shaft and support insulators are required to maintain thetemperature above dew point which lies between 80-115 deg C. If temperature falls below the range as mentioned there will be a continuous tracking of electrical field over the surface of insulator which will result into damage of insulator and non a vailability of field for collecting the fly ash. We in Heatco after continuous R & D detected the importance of the Heating Elements for ESP and as per the requirement developed the Heaters for its smooth functioning. We are providing some of the types of heating elements provided at hopper and support and shaft insulator. There are others which can be made as per customers design to suit its application. vailability of field for collecting the fly ash. We in Heatco after continuous R & D detected the importance of the Heating Elements for ESP and as per the requirement developed the Heaters for its smooth functioning. We are providing some of the types of heating elements provided at hopper and support and shaft insulator. There are others which can be made as per customers design to suit its application.

|

| |

| |

| Different Types of Tubular Heating Elements |

|

Tubular Elements Form #1

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

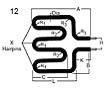

Tubular Elements Form #12

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

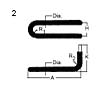

Tubular Elements Form #2

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

Tubular Elements Form #13

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

Tubular Elements Form #3

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

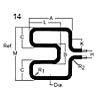

Tubular Elements Form #14

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

Tubular Elements Form #4

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

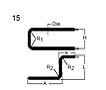

Tubular Elements Form #15

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

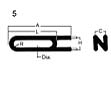

Tubular Elements Form #5

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

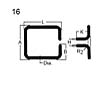

Tubular Elements Form #16

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

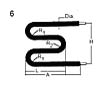

Tubular Elements Form #6

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

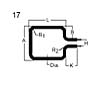

Tubular Elements Form #17

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

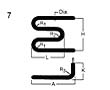

Tubular Elements Form #7

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

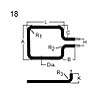

Tubular Elements Form #18

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

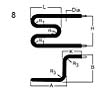

Tubular Elements Form #8

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

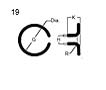

Tubular Elements Form #19

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

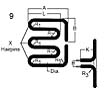

Tubular Elements Form #9

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

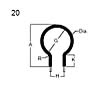

Tubular Elements Form #20

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

Tubular Elements Form #10

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

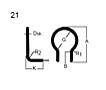

Tubular Elements Form #21

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

Tubular Elements Form #11

Tubular Heating Elements, the most versatile of all types, are used for practically the entire range of electric resistance heating applications. |

|

|

|

| |

| Click for larger view |

|

|

|

|

|

|

|

|