JOINTMASK

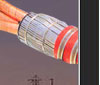

PUSH-ON IS SUITABLE FOR SECTOR-SHAPED AND CIRCULAR CONDUCTOR

CABLES

The

elasticity of the EPDM material, together with the technique

of achieving a high quality interface between the stress cone

and outer semi-conducting screen allows JOINTMASK PUSH-ON

to be used on sector-shaped or circular compacted conductor

cables. The

elasticity of the EPDM material, together with the technique

of achieving a high quality interface between the stress cone

and outer semi-conducting screen allows JOINTMASK PUSH-ON

to be used on sector-shaped or circular compacted conductor

cables. |

JOINTMASK

PUSH-ON has an creepage of 4 cm /

KV, which is adequate even under severe environmental conditions. JOINTMASK

PUSH-ON has an creepage of 4 cm /

KV, which is adequate even under severe environmental conditions.

JOINTMASK PUSH-ON

is provided with creepage current collector (as indicated

in the illustrations) with Outdoor Terminations so as to allow

and collect the leakage current across the termination surface

, avoiding any damage to the terminations. |