| Heat

Shrinkable Joints & Terminations >> |

|

|

Heat Shrink Cable Termination

Systmes

Our constant interaction with the

end users of cables has provided us in-depth information

of all customers problems, from concept to commissioning.

Today Master Electricals is involved not only in manufacturing

and marketing cables and cable accessories, but it

is also a total cable company whose activities, include

cable laying jointing commissioning and special technical

training programmes for customers.

|

|

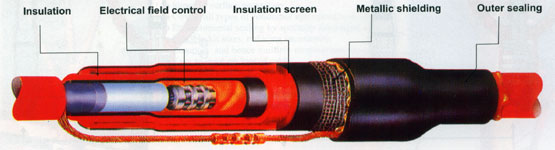

Master Electricals

Heat Shrink Cable Termination

Systems comprise of material in an expanded form, which

on application of heat, shrinks down to a predetermined

diameter adhering to any conductor size in between firmly,

and simultaneously the inside coating if any , melts

and seal the ends. Hence in a single step, insulation

and perfect environmental sealing is achieved. |

|

| |

Unique Features

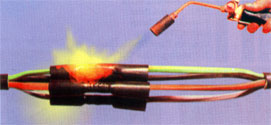

Heat

shrinkable terminations offer many distinct advantages over

conventional systems. Heat

shrinkable terminations offer many distinct advantages over

conventional systems.

• Quick and easy to install

• Effective and reliable stress control

• Superior surface protection

• Covers all types of conductor and connection shapes

• Environmental sealing by specially developed sealants

• Flexible kit sizes, reducing inventories

• Compact and hence multiple terminations possible

• Easy to open no loss of cable

• Unlimited shelf life

• Reduced down time

• Immediate energization of cable on completion

• Minimal structural support required

|

| Designed to Meet International

Specifications |

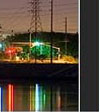

Stress

Control : Stress

Control :

Heat shrinkable electrical

stress control material has a carefully controlled volume

resistivity and permittivity, thus providing an electrical

stress control function at I end of the cable screeen, by

a defined impedencc characteristic. The installed tubing supresses

electrical discharges to prevent insulation damage in service.

In the case of belted cable it is necessary to provide electrical

continuity between the stress control tubing and the lead

or aluminium sheath. This is achieved by the use of conductive

heat - shrinkable moulded parts with very low electrical resistance.

|

| |

Surface Protection

Early experiments at 11 kv demonstrated

the need for special tracking resistance materials

for use at high voltages. These material had to be

non-tracking nor only in clean environments, but also

in the presence of dust, smoke and other contaminants

of outdoor environments.

The material used in Heat Shrink terminations has

superior surface properties whereby it can withstand

the most severe external environment without tracking.

All terminations have this surface protection as an

intergral part of the system.

|

|

Environmental Sealing

Terminations are environmentally

sealed, so that no air, water or contaminats can get

into the system.

Specially developed mastics and sealants are supplied

in the kits in tape or coating form. Coatings are in

the form of an inside lining of heat-shrinkable tubings

and cable breakouts. This coating on heating melts and

flows sealing the ends of the tubings and hence protecting

them from the environment. |

|

| |

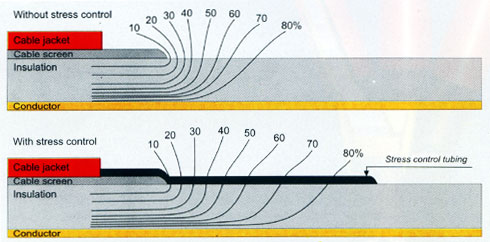

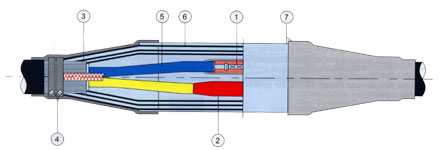

Heat

Shrink Termination Heat

Shrink Termination

For 1 core/3 core XLPE / PILC Cable From 22

Kv - 36 Kv Voltage

1 Lug Sealing Tape

2 Terminal Connector

3 Conductor

4 Terminal Sleeve

5 Anti Tracking Sleeve + Oil Barrier Sleeve (PILC)

6 Stress Control Sleeve

7 Rain Shed

8 Armor Bonding Braid

9 Stress Control Paint

10 Worm Drive Clamp

11 Copper Braid

12 Constant Force Spring Clamp

13 Trifurcatine Break Out |

| Heat shrinkable

HV straight through joints upto 72 kv for XLPE/PILC cables |

2.

High Voltage Power Cable Joints: 2.

High Voltage Power Cable Joints:

Heat shrinkable cable joint systems are

designed for all types of cables viz PILC, XLPE, PVC and

rubber insulated of single and multiconductor constructions

upto 72 kv. The joints are installed rapidly requiring far

less installation effort and time than epoxy/ polyurethane,

tape or premoulded kits. The kits reconstruct the jointed

cable with factory engineered and tested components and

provide a moisture proof environmental seal. A unique mechanical

protection system which far exceeds the requirements of

Engineering Recommendations and provides a strong and impact

resistant envelop around the jointed cables. The kits meet

or exceed IEEE 404, VDE 0278, and other international standards.

|

| |

|

| |

| Heat shrinkable

LV straight through joint for XLPE I PVC f PILC cables |

3.

Low Voltage Joints 3.

Low Voltage Joints

Joints for 2, 3 & 4 core PVC,PILC, XLPE

and rubber cables adopt the well proven heat shrink technique

to give water tight environmental sealing of the cables,

thereby . completely eliminating the need for compound or

resin filling. The result is a quick and economically installed

joint requiring no special skills. The joints cut handling

problems, have unlimited shelf life upto 500C and have mechanical

strength equal to or better than the cable itself.

|

| |

| Heat shrinkable

LV terminations for XLPE i PVC | PILC cables. |

4.

Low Voltage Terminators 4.

Low Voltage Terminators

Installed in millions throughout the world

and widely specified by electrical utilities, cable terminations

are acknowledged to the simpler, more reliable and much

cheaper to install than traditional systems. LV terminations

for PILC, PVC, XLPE and rubber cables are available.

|

| |

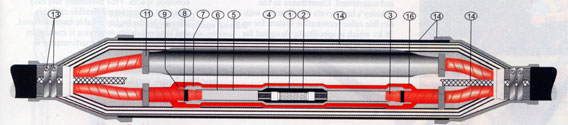

Heat Shrinkable

Straight Joints upto 36 kV

for XPLE/PILC

Insulating Cable |

|

| 1 In Line Connector

/ 2 Yellow Mastic / 3 Stress Control Paint / 4 Stress Control

Sleeve (Black) / 5 Insulating Sleeve (Red) / 6 Dual Wall Sleeve

(Red & Black) / 7 Red Mastic / 8 Stress Control Mastic /

9 Water barrier Sleeve / 10 Copper Woven Mesh Tape / 11 Constant

Force Spring Clamp (optional) / 12 Armour Continuity Connection

/ 13 Worm Drive Clamp / 14 G. I. Corrugated Outer Mesh / 15

Outer Protection Sleeve. |

| |

Heat Shrinkable

Straight Joint

for 1.1 KV PVC / XPLE

/ EPR / LT. cable |

1

In line Connector 1

In line Connector

2 Insulation Sleeve

3 Armor Continuity Connection

4 Worm Drive Clamp

5 Cable Insulation

6 G. I. Carrugated Mesh

7 Outer Jacking Sleeve |

| Go

to top ... |