|

|

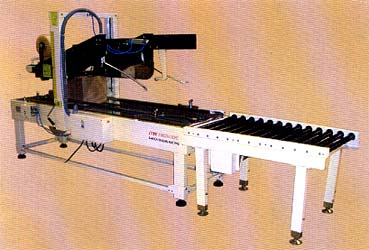

FTM 550 Semi

automatic carton sealing machine with Flexible Taping Head

FTM 550 Semi automatic carton sealing machine is ITW Signode's

innovative solution to meet a variety of carton sealing

needs:

ADVANTAGES: ADVANTAGES:

-

Reliable, robust design

-

Ideal for batch production

-

Auto-Off Switch

-

Carton Counter with electronic digital

display

-

New 'Soft' taping head with in built

two arm tape holding mechanism results in smooth movement

-

Variable tape overlap up to 75mm

-

Works with high tack tapes too

-

Self-centering side guides for accurate

centering

-

Sturdy and simple top drive set bracket

-

Positive top and bottom drive to ensure

sealing of tall and heavy cartons, in addition to regular

cartons

-

Easy top belts replacements

-

Belt conveyors for smooth transfer

-

Belt speed of 20 JIl/minute as per

international norms

-

Belt Guards

-

Inbuilt Tool Box

-

The machine's telescopic legs provide

for bed height adjustments to match conveyor or packing

station height, as the case may be

Any box ration approaching this limitation

should be test run to assure performance.

The machine's performance depends on the quality of carton,

tape and the materialfitment in the carton

SPECIFICATION:

| |

Minium |

Maximum |

| Carton

size [mm] |

|

|

| Length

|

150 |

Unlimited |

| Width |

160 |

550 |

| Height |

100 |

550 |

| Carton

weight carrying capacity (Kg) |

50 |

- |

| Machine

size [mm]

|

| Length

|

160

(including 0.5meter conveyor) |

- |

| Width |

800 |

- |

| Height |

1500 |

- |

| Motor |

2

Nos of 0.25 Hp |

- |

VoltagelFrequency

|

230

V AC, 1PH 50 Hz |

- |

| Power

Consumption |

360

Watts |

- |

|

| |

An Economic Solution

to your Taping & Strapping needs |

| |

FEATURES

& BENEFITS: FEATURES

& BENEFITS:

- Self Centering mechanism

- Extended side drive holds cartons for better strapping

- Logic Control through PLC

- Elimination of powered roller conveyor between taping

and strapping equipment improves throughput

- Straps and tapes up to 8 cartons per minute

- Zero, one or two straps can be applied

Machines can be used on line, stand alone or separately

OPTIONS:

- System auto stop and carton counter

- Powerised top drive for cartons having weight between

40 to 60 kgs

- Idler roller conveyor attachment for CSM to use it stand-alone

Three straps

SYSTEM SPECIFICATIONS:

| Machine

Size |

1313(L)

x 900(W) x 1715(H) |

| Power

Supply |

3

phase, 415V, 50Hz |

| Carton

Length(mm) |

300

to 700 |

| Carton

Width(mm) |

200

to 500 |

| Carton

Height(mm) |

150

to 500 |

| Carton

Weigth(kg) |

5

to 40 |

| Belt

Speed |

20meters/minute |

| Tape

Size |

2",

2 1/2" or 3" |

| PP

Strap WIdth (mm) |

9,12,15 |

| Tension

Adjustment (Kg) |

Max.

90 |

| Power

Consumption(kw) |

1.225 |

| System

Dimension (mm) |

1653(L)x1440(w)x1715(H) |

|

| |

Fully Automatic

Carton Sealing Machinme (The 5FAM adventure) |

| |

The

5FAM can easily be integrated with a high speed batch production

line to increase productivity - which results in saving money

and time. The

5FAM can easily be integrated with a high speed batch production

line to increase productivity - which results in saving money

and time.

PRODUCT FEATURES:

Four flap closer

Belt speed of 20 meters / minute

Consistent overlap of tape results in consumable savings

Quick and easy adjustment between batches of different carton

sizes

ACCESSORIES:

Regulatory cum centering conveyor to regulate the

flow of cartons and center them on the horizontal axis prior

to taping.

Idle roller conveyor, which acts as a buffer between the machine

and the carton collecting station.

The Bottom Sealer is the ideal alternative to manual bottom

taping. Top plate can be provided as an option.

PRODUCT SPECIFICATION:

| Length |

2100mm |

| Weight |

730

mm |

| Height |

1530mm |

| Weight |

250kg |

| Motors |

0.25hp,

220V, 180Watts-2 Nos. |

| Power |

360

Watts |

| Air

Consumption |

0.8

ltr/cycle at 5kg/cm2 |

|

|

|