|

|||||||||||||||

|

|||||||||||||||

|

|

|

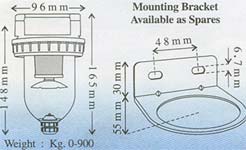

Filteration of compressed air removes water, oil, dirt and other contaminants, protecting air-driven equipments and instruments. Airchamp Turbo-flow

Filters are exceptionally efficient in removing impurities

with minimum pressure drop. Based on baffle system of first moisture

& impurities separation and then secondly filtering

through the pure sintered bronze element. Available in three

pipe sizes of 1/4 - 3/8 - 1/2 BSP Maximum pressure 250

psig. Maximum temp. 50°C. Polycarbonate transparent bowl

of 230 ml. capacity with easy operating manual drain cock.

Available with Mettalic Bowl Guard also. Filter is standardly

supplied with 25 micron element,5 micron or 50 micron available on

order. Body pressure die cast zinc alloy / LM6. Parts acetal.

Seal gaskets buna / viton. |

||||||

|

||||||

To minimize wear tear-and rusting of pneumatic valves, cylinders, components and tools, it is essential to keep them properly lubricated for best performance and long service life. Lubricators conveniently inject the oil directly into the air pipe lines, as carefully metered fine mist / fog, thus automatically lubricating all parts of air-operated equipment. Airchamp Lubricators provide exceptionally high

performance over a very wide flow range, without excessive pressure

drop. The oil is easily set to the desired feed rate with the

adjusting knob and once the rate is set, the lubricator

automatically adjusts the drip rate proportional to variations in

air flow. The oil drop rate is clearly visible in the sight

feed dome. Fine S. S. mesh is provided at the suction end to protect

the oil from dirt and particles. One oil filling port and one vent

valve button is provided on the body of the lubricator to

depressurise the bowl for filling oil without shutting off the air

supply. Available in three pipe sizes of 1/4 - 3/8 - 1/2 BSP.

Maximum pressure 250 psig. Maximum temperature 50°C. Polycarbonate

transparent bowl of 230 ml. capacity. Available With Metallic

Bowl Guard also. Body pressure die cast zinc alloy / LM6. Parts

acetal. Suction tube brass. Seal gaskets buna /

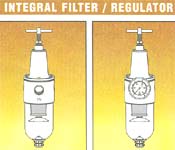

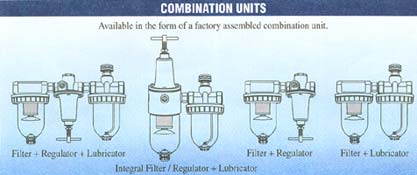

viton.Where cost and space is

critical but the height permits, the integral filter/regulator

offers the economy of space and cost. |

||||||

|

||||||

|

||||||

|

||||||

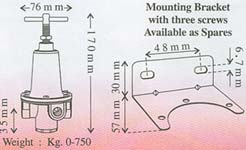

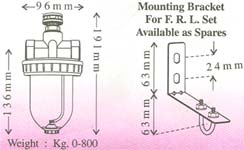

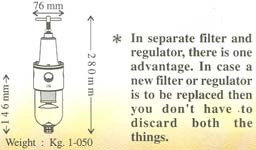

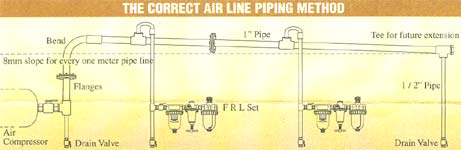

It is ADVISABl.E to use the filter or lubricator with METALLIC BOWL GUARD for enhanced . SAFETY requirements to avoid personal injury and / or property damage. Polycarbonate bowl SHOULD NOT be exposed to synthetic lubricants, alcohols, glycols, liquified . petroleum gases or harmful chemicals or their fumes as they can possibly cause the polycarbonate bowl to burst. Use only non-detergent mineral base oils. Clean the bowl with soap water only. DO NOT use solvents, thinners, acetone or carbon tetra-chloride etc. One pair of Mounting Brackets are supplied free with all the combination units. It is RECOMMENDED to install the filter or lubricator or FRL unit as near as possible to the point of use. Our products are Fully Guaranteed, as they are carefully planned, inspected and tested for quality at every stage of manufacturing. However, our obligation under this warranty is limited to repai r or replacement of the defective product. All the parts are available, ask for the list of spares. We have a policy of continual product development and therefore reserve the right to modify products/parts shown in this catalogue, without any notice. |

||||||

| Top |